About Us:

B11 STANDARDS, Inc. 7114 Rancho Mirage, Houston, TX (832-446-6999)

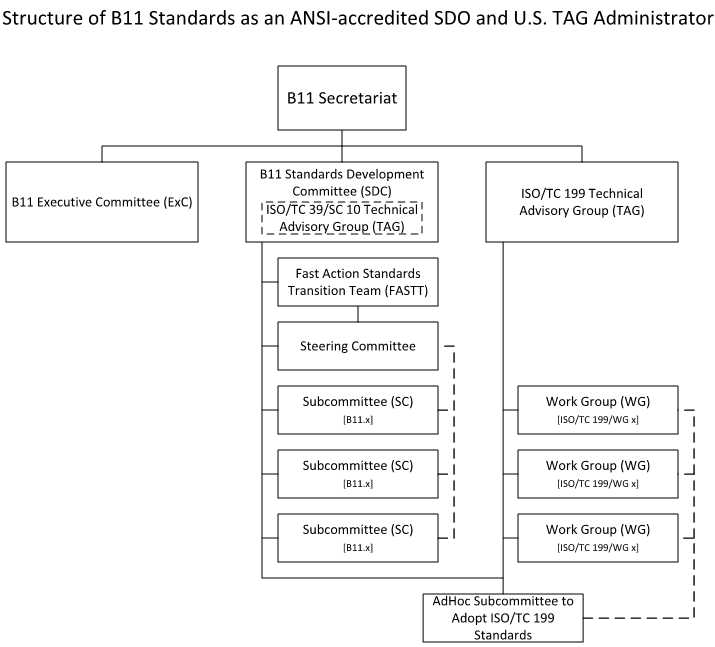

B11 Standards, Inc. is one of the ~230 ANSI-accredited Standards Developing (ASD) organizations in the United States that administers the process through which the ANSI B11 series of American National Standards and Technical Reports on machine/machine tool/machinery safety are developed and approved. Founded in 2010, B11 Standards Inc. is also accredited by ANSI as the United States Technical Advisory Group Administrator to ISO Technical Committee 199 (machinery safety standards) as well as ISO Technical Committee 39 Subcommittee 10 (machine tool safety standards).

B11 Standards Inc. also participates in a large number of additional national and international standards development activities to facilitate alignment where possible.

Past

Standardization / standards provide a bridge between research, innovation and the market, thereby strengthening competitiveness and boosting growth and jobs. Standards are a valuable tool for market dissemination of research and development results and can therefore contribute to the objectives of overall market innovation and competitiveness.

The project on Safety Standard for Power Presses, B11, was initiated under the procedures of the American Engineering Standards Committee (which became the American Standards Association, the United States of America Standards Institute, and in 1969 the American National Standards Institute - ANSI), with the National Safety Council as sponsor. The first standard, bearing the title Safety Code for Power Presses and Foot and Hand Presses, was developed by Sectional Committee B11 and was approved on November 13, 1922. Only two purposes of that "code" were listed. The first and primary purpose was for state industrial commissions in developing their workplace codes. The second purpose was as an operating guide for users operating press production systems.

Revisions of the first B11 standard were issued in 1926, 1937, 1948, 1960, 1971, 1982, 1988, and 2001 and 2009. The Association For Manufacturing Technology (AMT) assumed this activity from the National Safety Council in 1970 and administered the activity until 2010, when they transferred it to B11 Standards. Inc., which is now the ANSI-Accredited Standards Developer (ASD) for the B11 series of safety standards for machines and is the Secretariat for the B11 Standards Development Committee (SDC).

B11 Standards, Inc. is also accredited by ANSI as the United States Technical Advisory Group (TAG) Administrator to two International Standards Organization (ISO) Technical Committees (TC), ISO/TC 199 on Machinery Safety and ISO/TC 39 /SC 10 on Machine Tool Safety.

Present

The B11 SDC is comprised of over 30 national and/or global organizations representing multiple different stakeholder groups having a substantial interest and competence in the overall scope of B11 standards. It is recognized by ANSI as the consensus body that evaluates and votes on final draft standards (or technical reports) developed by B11 writing subcommittees for approval as American National Standards and ANSI Technical Reports. Each of the standards and technical reports within the B11 series has its own writing subcommittee. These subcommittees function somewhat autonomously from The B11 SDC, with their own Chair (and possibly a Vice-Chair or even a co-Chair), however, they are ultimately responsible and answerable to the B11 SDC. Once they complete work on drafting their document, it is turned over to the Secretariat for procedural commenting and balloting by the public and the interested Voting Group of B11 SDC Member organizations, which forms the actual "consensus body." Once this process has been completed, the candidate standard is submitted to the ANSI Board of Standards Review for approval as a new or revised (or reaffirmed) American National Standard.

Future

The B11 SDC has historically, and it ongoingly attempts to align its standards internally across the series by adopting a common format and dealing with recurring topics consistently (e.g., supplier/user responsibilities and risk assessment). This can prove challenging when individual writing subcommittees meet to begin revisions and invoke continuous improvement on the work of those before them. As one can easily imagine, it does not take long for inconsistencies to develop.

For that reason and many others, such as more efficient administration and most importantly, ease of the actual use and readability of these safety standards, the B11 SDC has developed a systematized approach to its series of safety standards, similar to the ISO (and CEN) approach of Type-A, Type-B, and Type-C standards, and has developed standardized sections (subclauses) that are consistent (boilerplate) that will remain uniform and standard across the series.

The B11 SDC remains committed to working closely with our European and other international colleagues toward the close alignment with both European norms and international general machinery safety standards developed in ISO/TC 199, and machine tool safety standards developed in ISO/TC 39 /SC 10.

B11 SDC scope

Standardization of concepts, general principles and requirements for safety of machinery incorporating terminology, methodology, and risk reduction measures for new, existing, modified or rebuilt power driven industrial and commercial machinery, not portable by hand while working. This includes associated equipment that may be used in the production system.

Procedures

While the U.S. TAG to ISO/TC39 /SC10 operates under the ANSI Model Procedures, the U.S. TAG to ISO/TC 199 operates under modified and approved ANSI Model Procedures. The B11 SDC uses its own standards development Operating Procedures, which conform to or exceed the ANSI Essential Requirements and are subject to periodic review and approval by the ANSI Executive Standards Council.

THE AMERICAN NATIONAL STANDARDS INSTITUTE: WHAT IS IT? WHAT DOES IT DO?

The American National Standards Institute (ANSI) is a federation of the nation’s leading trade, technical and professional organizations, corporations, government agencies, labor and consumer groups engaged in or concerned with developing and promulgating American National Standards (ANS). To date, there are over 11,000 voluntary consensus standards approved by ANSI that cover a very wide variety of products.

ANSI is not a government agency and does not write or publish voluntary consensus standards. ANSI is the autonomous umbrella standards body that provides and enforces model consensus procedures by which groups like the B11 Standards Development Committee may write standards for subsequent ANSI approval. (“B11” is the ANSI designation for our series of machinery safety standards.)

As Secretariat for the B11 SDC and one of the ~230 organizations in the United States that is formally accredited by ANSI to develop American National Standards, B11 Standards, Inc. adheres to ANSI’s procedures for consensus and due process.

THE B11 ACCREDITED STANDARDS COMMITTEE: WHAT IS IT? WHAT DOES IT DO?

The B11 Standards Development Committee (SDC) is the ANSI-accredited consensus body of organizations representing different interest areas having a substantial concern with and competence in the overall B11 mission. It represents a diverse balance of interest groups, which collectively determine the state of the art for machine tool safety.

The primary objective of each B11 safety standard is to eliminate injuries to personnel associated with machinery or a machine tool by establishing requirements for the construction, maintenance and operation of the machinery. To accomplish this objective, individual groups of knowledgeable experts form relatively autonomous Subcommittees under the direction of the B11 SDC and Secretariat. These Subcommittees represent the technical writing arm of the B11 SDC.

Before a B11 Subcommittee draft standard can be submitted to ANSI for approval, it must be reviewed by two consensus arenas. The draft is circulated for comment and voting via formal official letter ballot to the B11 Standards Development Committee, and is also concurrently announced by ANSI for Public Review.

Once the candidate standard is approved by the ANSI Board of Standards Review, it is published by the Secretariat as a new (or newly revised) ANS. The B11 SDC must review each standard in its portfolio and make a determination on the 5th year of its approval date whether to revise (based on needed updates, technological advancement etc.) or simply reaffirm the document for another five years. Occasionally, a standard may be withdrawn as no longer relevant or subsumed within a similar standard.

Sponsors

The B11 standards and technical reports can be associated with the ISO “type A-B-C” structure as described immediately below, and as shown in Figure 1.

Type-A standards (basis safety standards) give basic concepts, principles for design, and general ‘foundational’ aspects that can be applied broadly across different types of machinery;

Type-B standards (generic safety standards) deal with one or more safety aspects or one or more types of risk reduction measure that can be used/applied across a wide range of machinery;

Type-C standards (machine safety standards) deal with detailed safety requirements for a particular machine or group of machines.

Hybrid standards which represent an evolutionary development of standards which combine some percentage of the typical content and requirements found in any two (or even all three) of the standard types described above. Usually (though not always), they are some amalgamation of type-A and type-C standards.

The ANSI B11.0 standard on general machinery safety is a “type-A” standard in that it applies to a broad array of machinery/machines and contains very general requirements. However, in some areas it also contains very specific requirements. B11.19, B11.20, B11.21, B11.25, B11.26 and the entire B11 series of Technical Reports are all typical “type-B” documents addressing general safety elements that can be used across a wide range of machinery (such as B11.19 on safeguarding, B11.26 on functional safety or B11.TR1 on ergonomics) or as a standard when integrating machines into a system (B11.20). The B11 series of Technical Reports are informative documents that may be generally applied to many different machines, and as such would fall into the “type-B” category. The machine-specific “base” (type-C) B11 standards contain detailed safety requirements for a particular machine or group of machines.

Figure 1 — Organization of the B11 Series of Documents

The safety of machinery depends on the practical application of the risk assessment process. The type-A (B11.0) and type-B standards are intended to be used concurrently with the type-C (machine-specific) standards during the risk assessment process, by the supplier and user of machines. See Figure 2.

Figure 2 — How to use type-C standards

If a type-C standard exists, the hazards and risk reduction measures identified in the standard assists in the risk assessment process. Readers may rely on the type-C standard for this information, subject to any application specific hazards. If no type-C standard exists, the reader needs to identify the hazards for the particular application and applying risk reduction measures accordingly.

When a type-C standard deviates from one or more provisions dealt with by this standard or by a type-B standard, the type-C standard requirement generally takes precedence. Any deviation in conforming to a requirement of any standard should be carefully evaluated and based on a documented risk assessment.